Promoting the present and future of the port town of Yokohama by making bags [Yokohama Canvas Bags]

![港町・横浜を鞄づくりで今へ、未来へ発信する[横濱帆布鞄]](https://magcul.net/wp-content/uploads/2018/03/eced61dcba5b65471de84586340da769-1.jpg)

Manufacturing

Making things

Takumi's landscape

The scene of this issue

[Occupation] Bag craftsman

[Craftsman name] Yokohama canvas bag Yukio Suzuki

[Location] Yokohama/Bankokubashi

Carefully, carefully, and thoughtfully.

A corner that introduces manufacturing sites that make use of handicrafts.

This time, we will introduce special vinylon, which is used for ships etc.

Commitment to domestic cotton canvas and materials, Yokohama area code

Even the brand signature of “045”

Let's go to the familiar "Yokohama Canvas Bag".

Simple and functional things are beautiful. ``Yokohama Canvas Bag'' is a product that embodies these words. We omit unnecessary decorations and pay particular attention to materials and parts. The two main materials used are vinylon naval canvas, which is used on ships of the Japan Maritime Self-Defense Force, and domestic cotton canvas, which has a history of being successfully exported overseas since the early Showa era. ``We wanted to create a bag like no other, so we focused on materials unique to the port city of Yokohama.With the ultimate outdoor specs, we want to promote high-quality products rather than mass consumption,'' says Suzuki. Made of durable, high-quality materials, details that take into account the senses of the user, such as an easy-to-grip handle, and a design that exudes an aesthetic sense. Be sure to pick up some ``Yokohama originals'' at the shop next to the workshop at the foot of Bankokubashi.

2 minutes walk from Bashamichi Station on the Minato Mirai Line. ``Yokohama Canvas Bags'' has a workshop at the foot of Bankoku Bridge, which is also known as a spectacular night view spot in Yokohama. Next door is a shop that has been renovated into a space that was previously used as a workshop.

Yukio Suzuki, who previously worked at an apparel company, decided in 2013 to ``make something by himself'' and ``create something unique to Yokohama,'' and founded ``Yokohama Canvas Bag.'' . During his time working at an apparel company, Suzuki witnessed hundreds of thousands of pieces of a single design being mass-produced in places like China. When starting his own brand, he decided to focus on ``manufacturing high-quality products that can be used for a long time, rather than mass consumption.''

When you enter the workshop, you will see a variety of things, including the main canvas fabric, colorful threads, parts such as zip-ups, and sample bags. Even though it was the first thing in the morning, Suzuki-san and other staff members at the workshop had already begun working quietly, cutting the fabric and sewing.

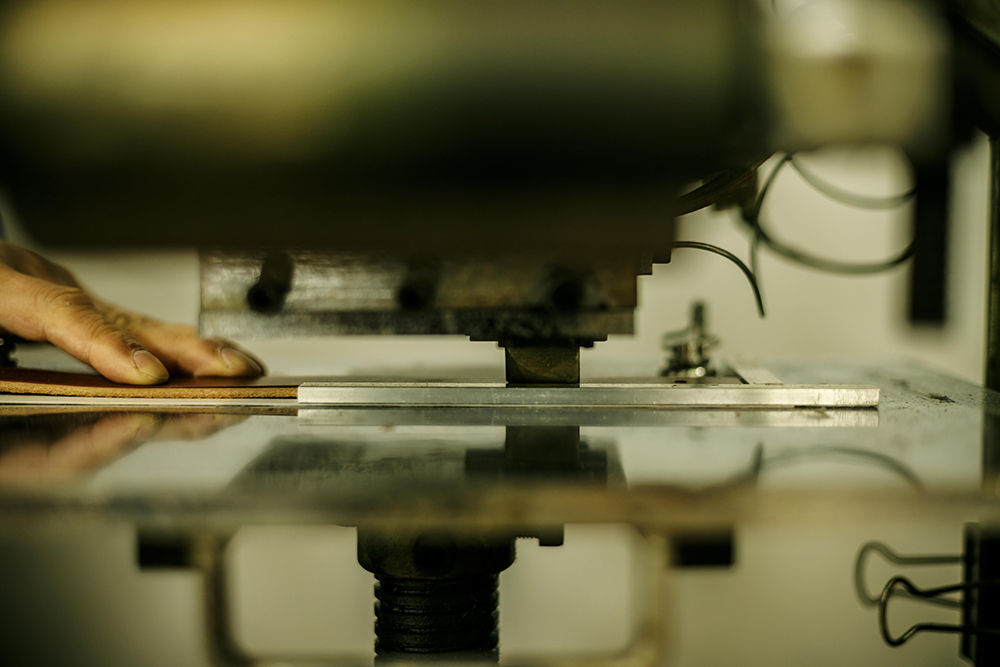

Holes are made in the sturdy vinylon canvas and parts are attached to the holes. A single bag is completed through a number of manual processes.

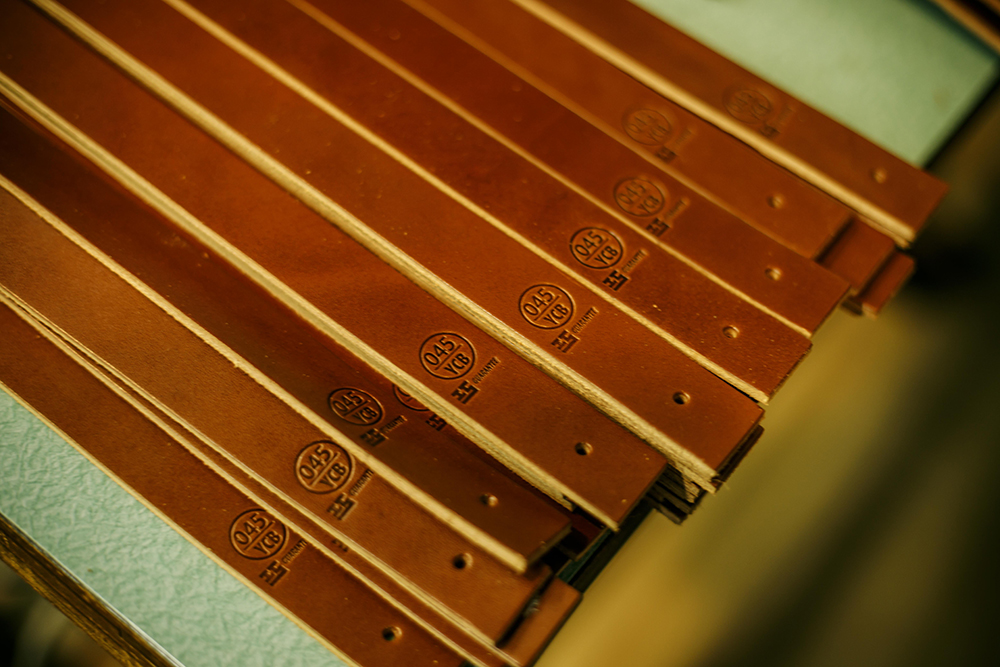

The photo below shows the process of chamfering a leather handle. A staff member at a store that sells ``Yokohama Canvas Bags'' told us that ``female customers had complained that the edges of the leather handles were touching their hands,'' and they immediately fixed the issue. From that time on, an additional step was added: chamfering.

You can make more pieces if you don't chamfer them. However, Mr. Suzuki continues to work on this chamfering process because of his desire to create better products that will satisfy the user. ``I'm very grateful that people are calling out the bad parts.No one praises the good parts because they are commonplace (lol), but I think that's okay.'' Mr. Suzuki, who says that Japanese people are good at inventing things to make them better, completed the chamfering of 600 pieces the day before the interview. There are 2 directions on both sides, so that means a total of 1,200 chamfers...It takes a lot of time to make it even better...

This is a press machine that stamps the brand signature "045" etc. on leather using heat of about 120 degrees. This kind of painstaking work is repeated on each and every handle of a bag that is used casually.

We also spoke about the materials that are important to Yokohama Canvas Bags. ``When launching this brand, I thought about what is unique to Yokohama.Yokohama is a port town, and in the past there was also a shipbuilding factory.Therefore, the two materials we currently use are ``Morino Kansen Canvas.'' Then I came across ``Takeyari cotton canvas.''

The first product, ``Morino Naval Ship Canvas,'' comes from Morino Canvas and Ship Equipment Co., Ltd., which was founded in Yokohama in 1914 as a ship equipment processing business centered on canvas and rope. This is a No. 4 naval canvas made of vinylon, an original vinylon material manufactured by Morino Canvas and Ship Equipment Industries, which is used on ships of the Japan Maritime Self-Defense Force. The other ``Takeyari canvas'' is from Takeyari Co., Ltd., which was founded in 1888 (Meiji 21). Long ago, there was a company called Yokohama Hanpu Co., Ltd. in Yokohama, which focused on overseas markets in the Showa era and successfully exported Japanese-made cotton canvas to Manchuria, China, Africa, Australia, and other countries around the world. Ta. High-quality Japanese cotton canvas was exported to the world from Yokohama...The main canvas production factory involved was the Takeyari Textile Factory (currently Takeyari Co., Ltd.) in Kurashiki, Okayama Prefecture. . (From Yokohama canvas bag homepage "Material & Parts")

Among these, there were concerns regarding the use of vinylon materials. Although the material is salt resistant, flame retardant, and UV resistant, it has excellent light resistance, but is it really suitable for making bags? ...``These performances themselves are not required for everyday bags.However, once we decided to create something unique and unique to Yokohama, we realized that the port city of Yokohama has the ultimate in everyday life. ``I wanted to pursue the outdoor specifications of the product, so I decided to take the plunge and use this material,'' says Suzuki.

Currently, Suzuki's main work is design and production, but he is also proficient with a sewing machine. While pressing the pedal with your foot, you carefully sew the strong material.

``I think there are many ready-made canvas bags.However, the products we make have a ``Yokohama Canvas'' concept.We are confident in that identity, while also creating comfort and joy in carrying it. I stand in the workshop every day with this thought in mind: I want more people to use it to enjoy it."

I also took a look at the shop next to the workshop. In light of the fact that the number of foreign visitors to Yokohama, a tourist destination, has begun to increase, the interior decorations are not limited to just "Yokohama", but have a broader definition, adding a touch of "Japanese" throughout. was. For example, in front of the cash register, there is this noren curtain. The mark that resembles a family crest is the brand signature "045".

A sewing machine is placed next to the cash register, and you can see the manufacturing process in Japan while looking at the products inside the store.

Furthermore, inside the store is a creative tea room called Hawaian, which is approximately 3 tatami mats in size. Based on the concept of ``NO BORDER,'' which means a hermitage where you can be at peace, the space not only holds tea parties, but also exhibits and sales of works by artists.

We have a wide variety of tote bags, body bags, and backpacks that are perfect for vacations and trips this coming season. We hope you will come across the ``Yokohama original'' that suits you in this convenient location where you can enjoy the sea breeze from Yokohama Port.