Tsukiji Type: Preserving the culture of type for the future, focusing on the beauty of uneven surfaces

![凹凸の美にこだわり続け活字文化を未来に残す[築地活字]](https://magcul.net/wp-content/uploads/2018/03/d2f334f762e29d7e47eacfec80cff685.jpg)

Manufacturing

Creating things

Craftsman's Landscape

This issue's site

[Occupation] Type casting craftsman

[Craftsman name] Tsukiji Typesetting Omatsu Hatsuyuki

[Location] Minami Ward, Yokohama

Carefully, slowly, and with thought.

A corner introducing manufacturing sites that make use of handwork.

This time, we will look at letterpress printing, which once supported Japan's printing culture.

Even in today's digital age,

He joined Tsukiji Type, which has gained support from many customers.

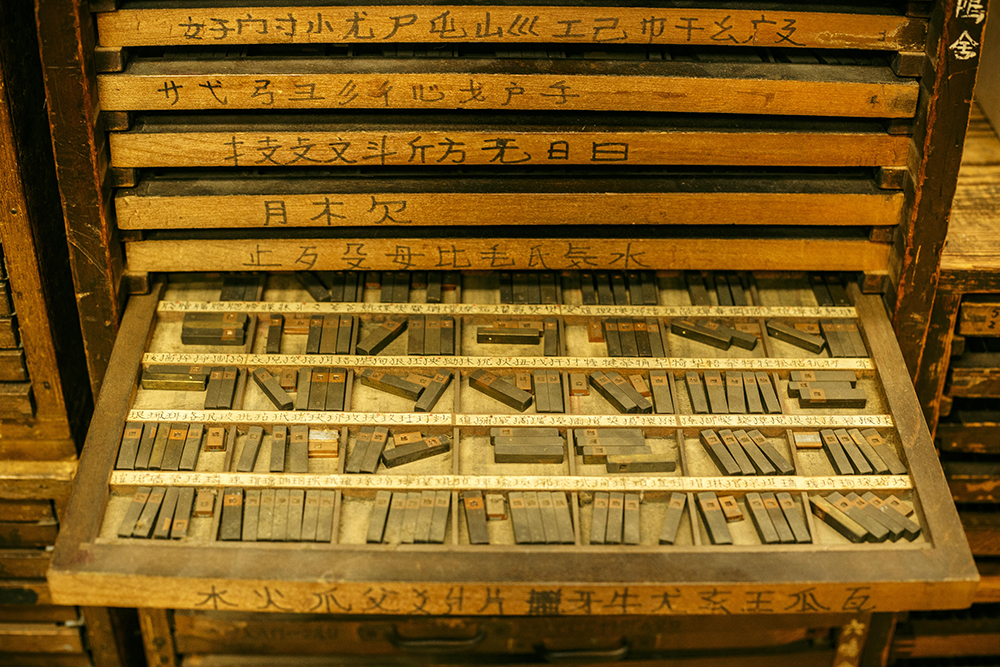

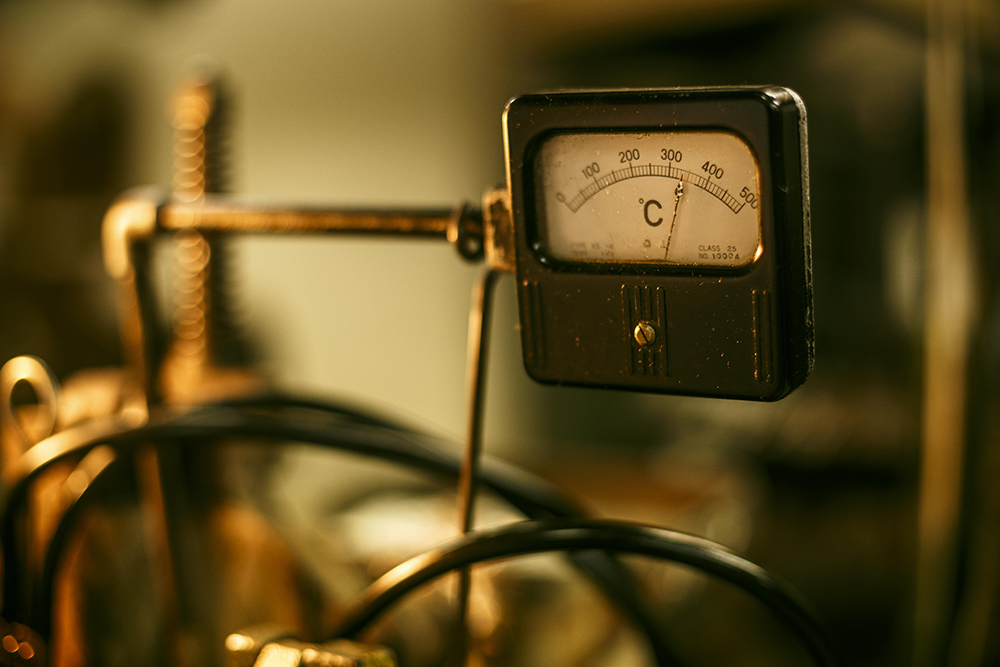

A worn wooden shelf known as the "Type Room" houses over 250,000 metal characters, including kanji, hiragana, and the alphabet. This is Tsukiji Type, founded in 1919 (Taisho 18). The loud mechanical noise at the back of the store is coming from a type casting machine. The raw metal (ingot), melted in a furnace at temperatures of 350-400 degrees, flows into a concave mold pre-installed in the casting machine, and as it is cooled with tap water, it emerges as convex type. Omatsu, who has been working as a foundry craftsman here since the age of 19, is now 73 years old. He occasionally pushes down his glasses to peer through a magnifying glass and inspect the freshly made type. This careful, high-quality work, which has been going on for over 50 years, continues to convey the charm of type to us today.

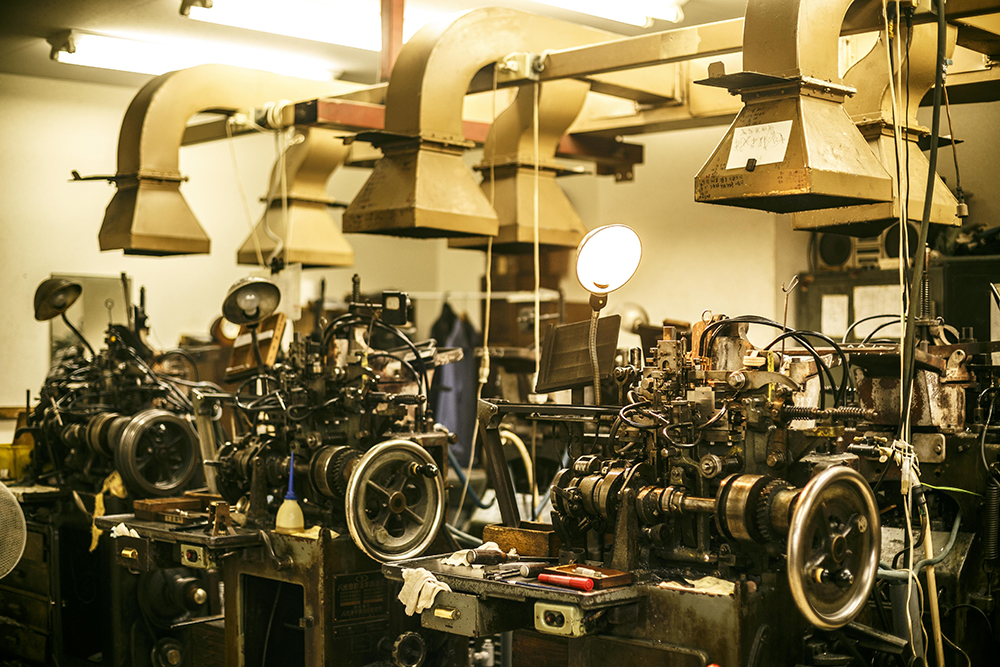

Tsukiji Type is located near Yoshinocho Station on the Yokohama Municipal Subway Blue Line, along the Nakamura River, which branches off from the Ooka River. When you open the door, you'll hear the loud clanging of machinery and the distinctive smell of burnt oil. The source of that sound and smell is the row of type casting machines lined up at the back of the room, where craftsman Omatsu stays nearby, watching over the machines' operation without leaving his side for a moment.

This time, we had the opportunity to speak with Kiichi Hiraku, the fifth generation owner of Tsukiji Type, who has taken over type casting and letterpress printing.

"There's something my father, the previous president, used to say that I'll never forget: 'The letters in old newspapers are less tiring on the eyes than the letters in modern newspapers. This is because the subtle differences in color intensity on the printed surface, caused by the unevenness of the letters set using letterpress, give your eyes a rest.' I now strongly feel those words myself. So, in today's society where digital printing is on the rise, I feel a mission to present to the world the artisanal techniques that create 'weighty' letterpress type as the unmistakable genuine article," says Hiraku.

With Hirako as our guide, we were shown the various tools and techniques related to letterpress printing that have survived through the ages and are still alive today.

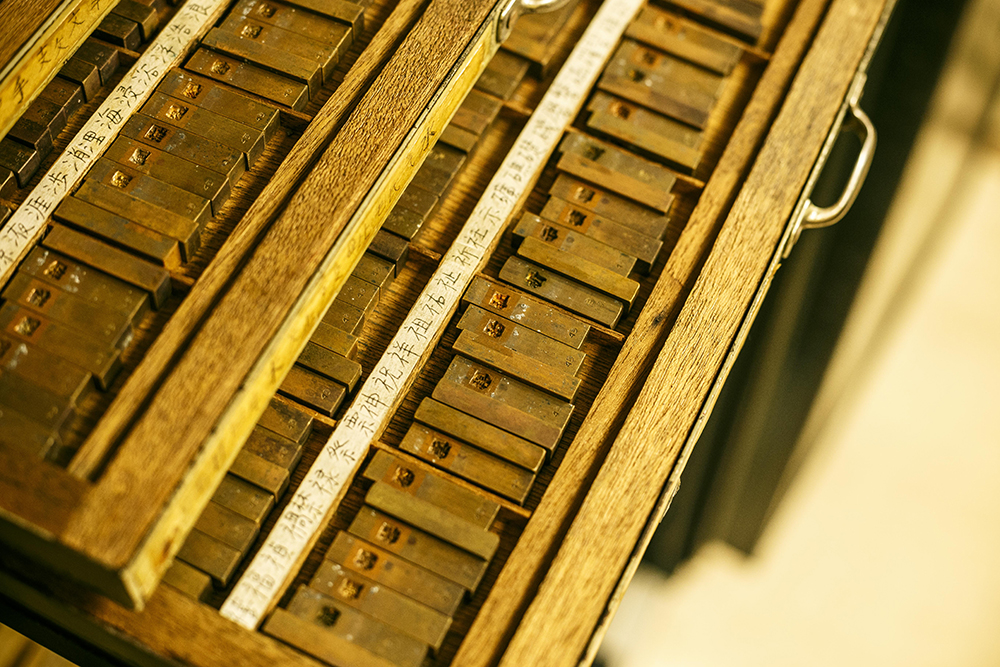

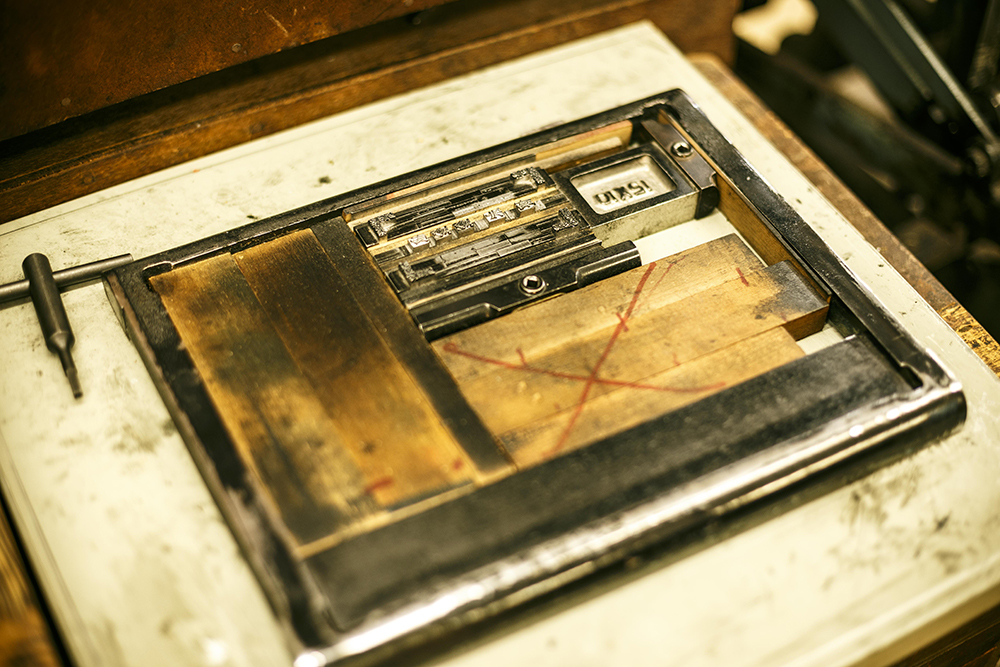

This is the so-called "matrix drawer," which houses the matrices, the casting molds essential for making type. Opening the drawer reveals rows of brass matrices. Tsukiji Type apparently stores matrices for over 250,000 character types, but since there are no longer any craftsmen who make these matrices, the items stored here are considered extremely valuable "treasures."

This "matrix safe" also houses valuable brass matrices.

When the raw metal (ingot) is poured into this concave part, it becomes raised type.

Next, we were shown the so-called "type room," which is filled with type created by foundry craftsman Omatsu.

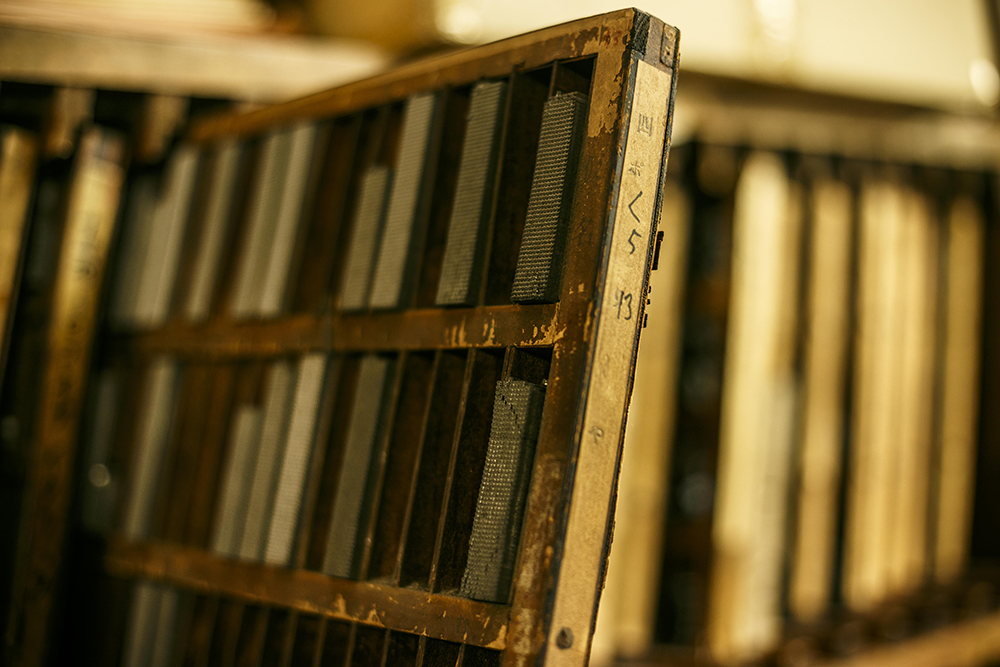

Why are the shelves stored at an angle? When I asked Hirako, he said, "The shelves containing the type are stored at an angle as a countermeasure against earthquakes. Because they are designed to be extremely balanced, the type is less likely to fly out in the event of an earthquake, and this style has been passed down for generations." It also seems that the way type is arranged varies depending on the printing company, but here at Tsukiji Type, the characters are arranged in the order they would be in an encyclopedia.

This is a type rack for the smallest 4-point type found at Tsukiji Type. The job of setting type like this has disappeared.

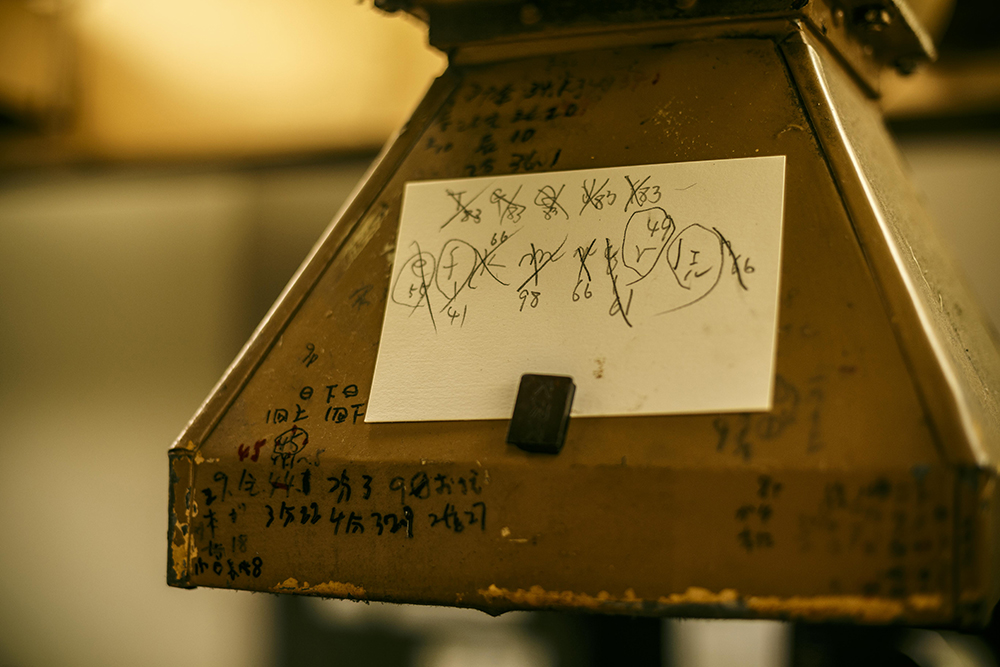

Next, we were given the opportunity to see the workplace of Omatsu, the craftsman who operates the type casting machine.

The raw metal (ingot) used to make type is made up of 83% lead, 15% antimony, and 2% tin.

In a type casting machine, the kettle is heated to 350-400 degrees, melting the aforementioned metal (ingot) into a liquid.

The liquid bullion that has accumulated in the center is.

Standing beside the casting machine, from which sweltering heat rises, Omatsu continues working for long periods of time, keeping an eye on the furnace.

A rod is placed in a pot containing molten metal, and the material's specific gravity and other "feel" are checked.

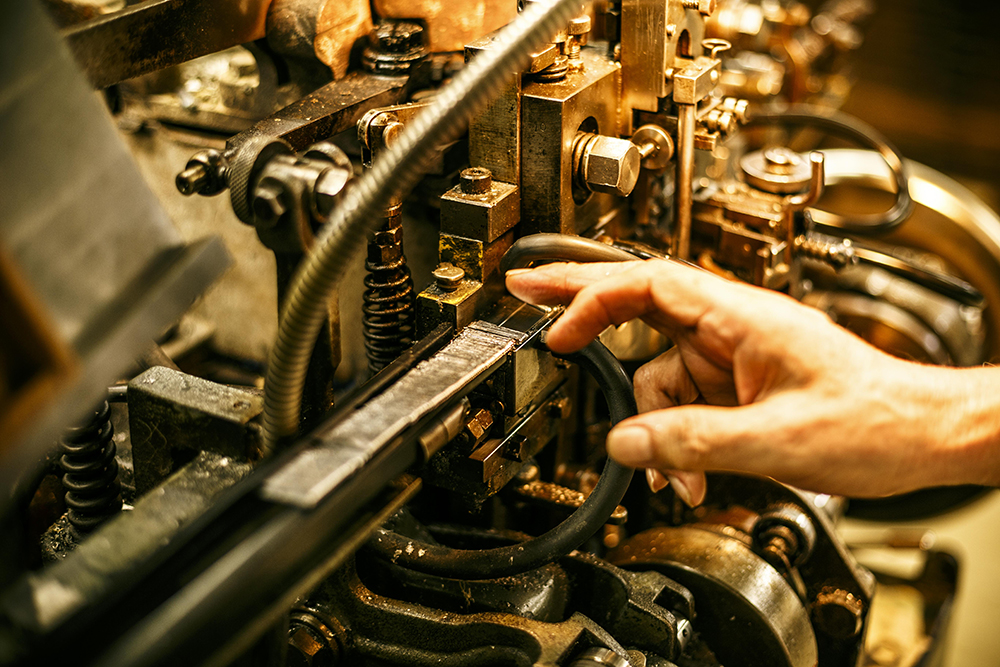

The metal melted in the kettle is then poured into a concave matrix.

The metal flows into the concave matrix and is cooled with tap water (photo above) until it becomes convex type.

The meticulous work continues by checking the completed tiny type with a magnifying glass. These tiny type are useless if they fall to the floor, as even the slightest scratch can ruin the beauty of the type.

Because there is a risk of steam explosions due to contact with water, the Fire Service Act requires that an exhaust duct be installed above the casting machine.

From here, Hirako-san will explain the basic steps of letterpress printing. First, type is selected in the "Type Room" to match the prepared manuscript, and then placed in the "Text Selection Box." After that, the type is placed in a metal frame called a "chase" while adjusting the spacing between the letters to create the printing plate, but this is quite difficult. It requires not only handwork but also the artisanal skill of "eye for quality," such as the exquisite use of space between characters and lines.

Finally, the chase is attached to a roller-equipped printing press, ink and paper are added, and the print is completed.

Tsukiji Type also sells type holders, which have been developed to bring the beautiful letterpress printing closer to people and allow them to use them for a variety of purposes. "I want people to experience the joy of setting and printing type themselves with this 'small tool,'" says Hiraku.

As an aside, I thought the appeal of letterpress printing was the deep unevenness it creates as if it were engraved into the paper (even the back side is bumpy), but he said, "It has long been said that artisans who press too hard in letterpress printing are no good. The key to skill is to express beautiful unevenness on the front side without letting it show through to the back side and without changing the appearance of the paper on the back side." I had the pleasure of hearing many profound stories.

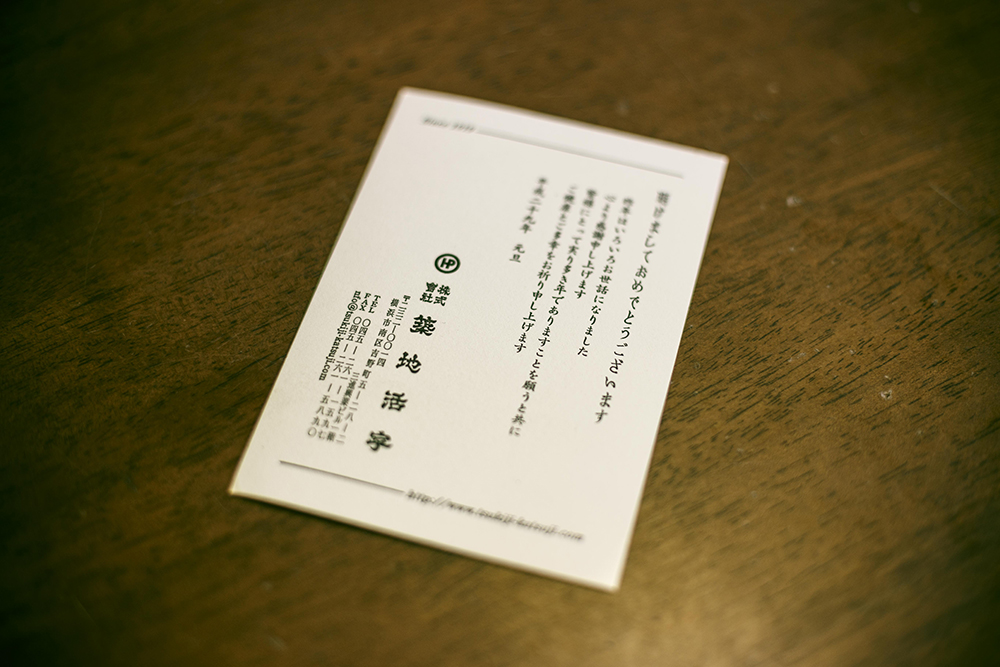

When I receive a letterpress-printed business card at work, I can't help but pick it up and stare at it. Today, I realized the reason why. It's just a business card, but it's a business card nonetheless. Inside that small square piece of paper that fits in the palm of your hand, the skills and thoughts of artisans that have been passed down through the ages are engraved. Why not try letterpress printing not only for business cards, but also for New Year's cards from now on? A New Year's card that will make people who pick it up admire the beauty of the letters and instinctively want to touch them gently with their fingers...